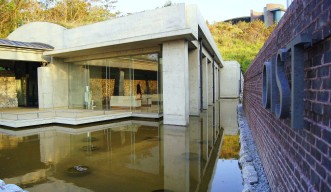

OIST Lab Wins Award for Sustainable Design

OIST’s Lab 2 has earned a green building certification in new construction under the internationally recognized standard, Leadership in Energy & Environmental Design (LEED), for its innovative design and construction. Only 32 other projects in Japan can claim this LEED certification, which recognizes that a construction project is environmentally responsible. OIST is currently the only building in Okinawa recognized by the program for new construction, and the only educational facility listed in Japan-- a notable achievement considering the amount of energy required to power a laboratory.

“In some parts of the world, LEED certification has become an attribute of the workplace that prospective employees actively seek out,” said John Dickison, vice-president of Buildings and Facilities Management.

The US Green Building Council oversees LEED, which was originally designed for North American buildings, but is becoming a global standard after certifying more than 13,000 construction projects in 135 countries. The certification system assigns points for a project in areas such as efficient water use, optimal use of energy and raw materials, indoor environment quality, design innovation, and overall site sustainability. OIST received sufficient points to win Silver status.

The team of architects, Nikken Sekkei/ Kornberg Associates/ Kuniken JV and the main contractors Nishimatsu Construction, Shinryo Corporation, and Toko Electric incorporated many eco-friendly aspects into the construction. They ensured the iron-rich soil did not flow into the waterways, but was recovered and reused in other projects like landscaping. OIST scored transportation points by providing a shuttle bus and stop within a specified distance from the exit of the building. LEED also recognized the importance of tying in the public airport bus through campus. Designating a certain number of parking spaces for low-emission vehicles (LEV) was also key.

“These were easy points for us,” said Dickison. “Most of the cars in Japan are already LEV, since they are under 2000 cc.” LEED favors transportation alternatives so the installation of several metal bicycle lockers also helped.

OIST highest marks - 10 out of 10 points - resulted from the efficient use of water. OIST recycles all water on campus. For example, the ultra low flow toilets in Lab 2 use recycled, treated water from the water treatment plant. Sensors in bathrooms minimize water flow from the faucets. And the irrigation and water features around campus use treated water.

Placing outdoor lighting low to the ground so as not to disturb wildlife, such as bats, also added to the tally. Consideration went into natural lighting for the building’s interior to help illuminate the rooms and corridors. Conserving energy by the ability to control the lighting racked up a few more points.

Construction materials that come from within 800 km also contributed--much of the concrete and stone used at OIST came from just 40 km away on the Motobu Peninsula.

Finally, OIST gained points with the lab’s innovative design, such as the unique sunshades lacing the outside.

“The challenge was to create an unprecedented international research community in the middle of a beautiful natural setting,” said Takashi Okamoto of Nikken Sekkei, who led the Japanese side of the design team. “We are excited to know that our enthusiasm and painstaking effort to create a socially responsible and environmentally-friendly facility was recognized in this global manner.”

Chief Architect for the American side of the design joint venture, Ken Kornberg, applauded the mission of LEED, and also felt proud of the recognition. “Gaining LEED certification for laboratory buildings is particularly challenging, given the energy requirements needed to purify air and water, and to operate vast amounts of research equipment,” he said. “OIST has made extraordinary efforts to develop and support cutting edge science while preserving the unique Okinawan ecosystem for future generations.”

The Buildings and Facilities Management division and the architects learned what they could improve upon when starting construction for Lab 3. “In some ways it will be easier,” said Dickison.

The plaque showing LEED SILVER status will arrive soon and be placed near the entrance to Lab 2.

For press enquiries:

Press Inquiry Form