Getting in Shape

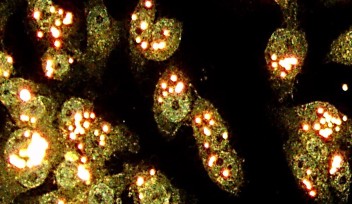

New research from the Micro/Bio/Nanofluidics Unit at the Okinawa Institute of Science and Technology Graduate University (OIST) looks at how to create various non-spherical particles by releasing droplets of molten wax into a cool liquid bath. The physics behind this research shows how a range of non-spherical shapes can be produced and replicated with many possible industrial applications. OIST Professor Amy Shen collaborated with her former Ph.D student Shilpa Beesabathuni from University of Washington, as well as The Procter & Gamble Company in the United States to conduct the research published in Journal of Colloid and Interface Science.

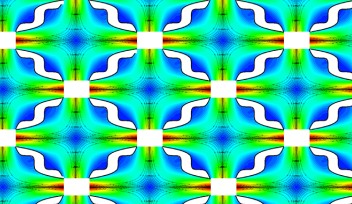

Non-spherical particles have a great deal of potential uses in industry because associated with their different shapes are properties such as large surface areas, high packing densities and unique responses to external electric and magnetic fields. Such properties can lend themselves to applications ranging from food processing, consumer goods such as cosmetics, absorbents, and drug delivery systems.

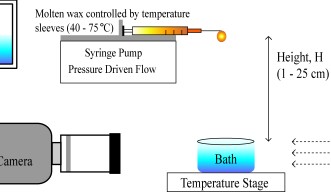

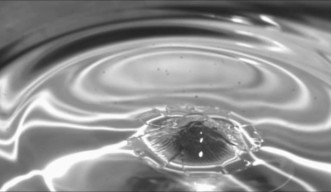

Prior research in creating non-spherical particles ranging from the micron to millimeters length scale has yielded production methods that are limited in scope and usually require the use of specialized equipment. The method used by Prof. Shen’s unit is simple, low cost, scalable, and applicable to many types of fluids. By forming molten liquid drops and releasing them into a bath of cooler liquid to solidify them, one can create a single non-spherical particle shaped by a combination of several variables acting on it from the moment of impact.

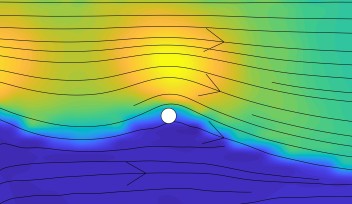

The physics behind the creation of different particle shapes through the use of impact and solidification between a molten liquid, in this case wax, and a cooler liquid medium were not entirely understood when this research began. In order to explore what shapes were possible, many different variables had to be taken into account, such as the temperature of the wax, temperature of the liquid bath, density and viscosity of the liquid bath, and the impact speed of the molten liquid drop.

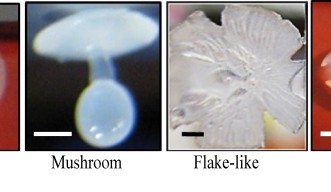

By balancing these different variables with competing time scales, four shapes presented themselves throughout the research: Ellipsoid, Mushroom, Flake-like, and Disc. In addition to the use of high speed image analysis, a simplified heat transfer model was used to estimate the time it takes for an individual molten wax drop to solidify after making contact with the cooling liquid bath. The resulting data allows for these four types of non-spherical shapes to be reliably reproduced and lays the groundwork for other types of particles to be created using similar methods.

Professor Shen explains “People have done studies similar to this in the past using liquid metals impacting solid surfaces, but not other liquids. In terms of the fundamental physics, I believe this research is unique. In terms of applications it’s also very important because of how simple and low cost this method is as well as how easily it can be scaled.” Wax based particles in particular with their low melting points would perhaps see use in the field of cosmetics but Professor Shen points out that similar methods can work with temperature sensitive polymeric and hydrogel materials, the same substances that are commonly used for capsules in pharmaceuticals, to provide new methods of making non-spherical capsules for drug delivery.

By Sean To

For press inquiries, contact media@oist.jp.

Specialties

Research Unit

For press enquiries:

Press Inquiry Form