Shedding Light on Dark Traps

A multi-institutional collaboration, co-led by scientists at the University of Cambridge and Okinawa Institute of Science and Technology Graduate University (OIST), has discovered the source of efficiency-limiting defects in potential materials for next generation solar cells and flexible LEDs.

In the last decade, perovskites - a diverse range of materials with a specific crystal structure - have emerged as promising alternatives to silicon solar cells, as they are cheaper and greener to manufacture, whilst achieving a comparable level of efficiency.

However, perovskites still show significant performance losses and instabilities. Most research to date has focused on ways to remove these losses, but their actual physical causes remain unknown.

Now, in a paper published today in Nature, researchers from Dr. Sam Stranks's group at Cambridge University's Department of Chemical Engineering and Biotechnology and Cavendish Laboratory, and Professor Keshav Dani's Femtosecond Spectroscopy Unit at OIST in Japan, identify the source of the problem. Their discovery could streamline efforts to increase the efficiency of perovskites, bringing them closer to mass-market production.

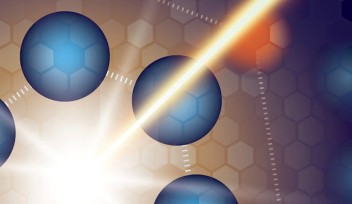

When light hits a perovskite solar cell or when electricity passes through a perovskite LED, electrons are excited and can jump to a higher energy state. The negatively-charged electrons leave behind spaces, called holes, which then have a relatively positive charge. Both excited electrons and holes can move through the perovskite material, and therefore act as charge carriers.

But in perovskites, a certain type of defect called a "deep trap" can occur, where energized charge carriers can get stuck. The trapped electrons and holes recombine, losing their energy to heat rather than converting it into useful electricity or light, which significantly reduces the efficiency and stability of solar panels and LEDs.

Until now, very little was known about the cause of these traps, in part because they appear to behave rather differently to traps in traditional solar cell materials.

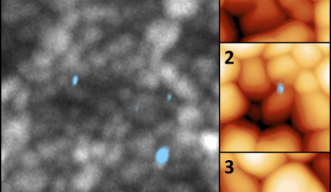

In 2015, Dr. Stranks's group published a Science paper looking at the luminescence of perovskites, which reveals how good they are at absorbing or emitting light. "We found that the material was very heterogeneous; you had quite large regions that were bright and luminescent, and other regions that were really dark," said Dr. Stranks. "These dark regions correspond to power losses in solar cells or LEDs. But what was causing the power loss was always a mystery, especially because perovskites are otherwise so defect-tolerant."

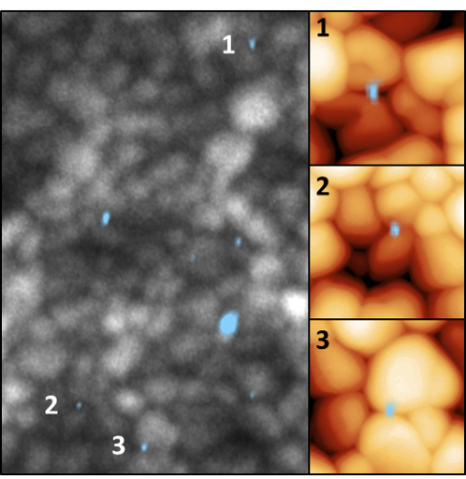

Due to limitations of standard imaging techniques, the group couldn't tell if the darker areas were caused by one, large trap site, or many smaller traps, making it difficult to establish why they were forming only in certain regions.

Later on in 2017, Prof. Dani's group at OIST published a paper in Nature Nanotechnology, where they made a movie of how electrons behave in semiconductors after absorbing light. "You can learn a lot from being able to see how charges move in a material or device after shining light. For example, you can see where they might be getting trapped," said Prof. Dani. "However, these charges are hard to visualize as they move very fast - on the timescale of a millionth of a billionth of a second; and over very short distances - on the length scale of a billionth of a meter.

On hearing of Prof. Dani's work, Dr. Stranks reached out to see if they could work together to address the problem visualizing the dark regions in perovskites.

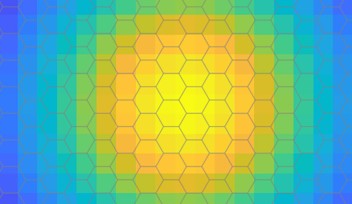

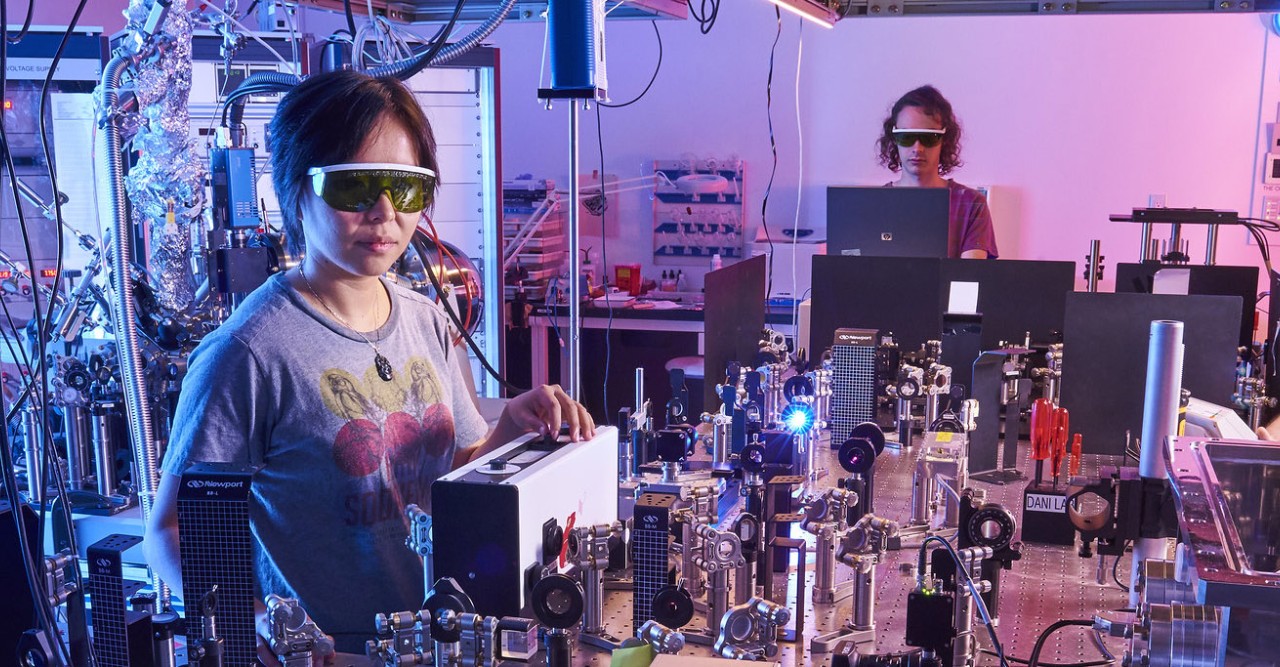

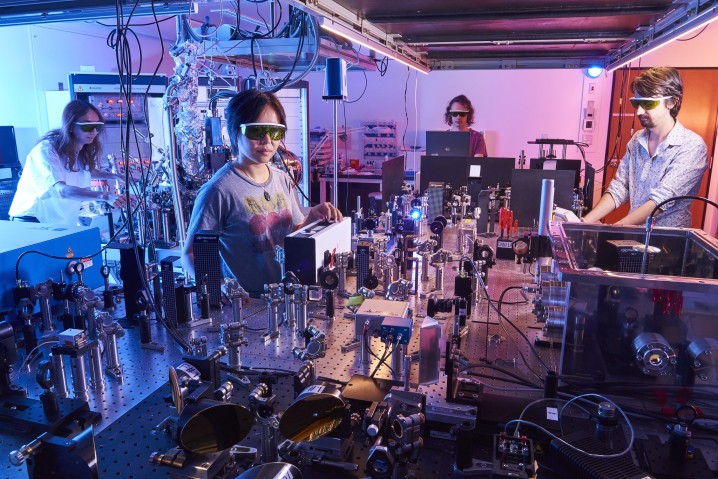

The team at OIST used a technique called photoemission electron microscopy (PEEM) for the first time on perovskites, where they probed the material with ultraviolet light and formed an image from the emitted electrons.

When they looked at the material, they found that the dark regions contained traps, around 10-100 nanometers in length, which were clusters of smaller atomic-sized trap sites. These trap clusters were spread unevenly throughout the perovskite material, explaining the heterogeneous luminescence seen in Dr. Stranks's earlier research.

Intriguingly, when the researchers overlaid images of the trap sites onto images that showed the crystal grains of the perovskite material, they found that the trap clusters only formed at specific places, at the boundaries between certain grains.

To understand why this only occurred at certain grain boundaries, the groups worked with Professor Paul Midgley's team from Cambridge University's Department of Materials Science and Metallurgy, who used a technique called scanning electron diffraction to create detailed images of the perovskite crystal structure. Prof. Midgley's team made use of the electron microscopy setup at the ePSIC facility at the Diamond Light Source Synchrotron, which has specialized equipment for imaging beam-sensitive materials, like perovskites.

"Because these materials are super beam-sensitive, typical techniques that you would use to probe local crystal structure on these length scales can actually quite quickly change the material as you're looking at it," explained Tiarnan Doherty, a PhD student in Stranks's group and co-lead author of the study. "Instead, we were able to use very low exposure doses and therefore prevent damage.

"From the work at OIST, we knew where the trap clusters were located, and at ePSIC, we scanned around that same area to see the local structure. We were able to quickly pinpoint unexpected variations in the crystal structure around the trap sites."

The group discovered that the trap clusters only formed at junctions where an area of the material with slightly distorted structure met an area with pristine structure.

"In perovskites, we have these regular mosaic grains of material and most of the grains are nice and pristine - the structure we would expect," said Dr. Stranks. "But every now and again, you get a grain that's slightly distorted and the chemistry of that grain is inhomogeneous. What was really interesting, and which initially confused us, was that it's not the distorted grain that's the trap but where that grain meets a pristine grain; it's at that junction that the traps form."

With this understanding of the nature of the traps, the team at OIST also used the custom-built PEEM instrumentation to visualize the dynamics of the charge carrier trapping process happening in the perovskite material. "This was possible as one of the unique features of our PEEM setup is that it can image ultrafast processes - as short as femtoseconds," explained Andrew Winchester, a PhD student in Prof. Dani's Unit, and co-lead author of this study. "We found that the trapping process was dominated by charge carriers diffusing to the trap clusters."

These discoveries represent a major breakthrough in the quest to bring perovskites to the solar energy market.

"We still don't know exactly why the traps are clustering there, but we now know that they do form there, and only there," said Dr. Stranks. "That's exciting because it means we now know what to target to bring up the performances of perovskites. We need to target those inhomogeneous phases or get rid of these junctions in some way."

"The fact that charge carriers must first diffuse to the traps could also suggest other strategies to improve these devices," said Prof. Dani. "Maybe we could alter or control the arrangement of the trap clusters, without necessarily changing their average number, such that charge carriers are less likely to reach these defect sites."

The teams' research focused on one particular perovskite structure. The scientists will now be investigating whether the cause of these trapping clusters is universal across all perovskite materials.

"Most of the progress in device performance has been trial and error and so far, this has been quite an inefficient process," said Dr. Stranks. "To date, it really hasn't been driven by knowing a specific cause and systematically targeting that. This is one of the first breakthroughs that will help us to use the fundamental science to engineer more efficient devices."

Specialties

Research Unit

For press enquiries:

Press Inquiry Form