Unlocking the Secrets of Okinawan Pottery

For generations, Okinawans potters have passed their expertise directly from master to student. There are no textbooks explaining how to make the beautiful pieces characteristic of Okinawa. Masters go by feel, colors, the shape of the flame. But with many potters incorporating modern techniques into their work as well as the loss of local clay sources, Okinawa risks losing the knowledge of traditional practices.

The Okinawa Institute of Science and Technology Graduate University (OIST) and Kitagama, a local pottery collective, joined together to scientifically document and investigate traditional Okinawan pottery practices. Using advanced instrumentation, OIST researchers studied the wide range of materials and techniques involved in making Yachimun, traditional Okinawan pottery.

The results of this scientific research and more than 200 pieces of pottery are now on display at OIST. The KITAGAMA x OIST exhibition runs from May 18 to July 31 on the main OIST campus.

“This is a special opportunity to help preserve the tradition and culture of Okinawa,” said Dr. Kenichi Sajiki, a researcher at OIST who spearheaded the project. “Local clay sources, which form the foundation of Okinawa pottery, are being paved over as the island develops. It is important to understand what is in the ideal mixture so potters can continue to mix new clay sources in the right proportions.”

Kitagama – which means North Kiln in Japanese – is located just 20 minutes south of OIST in the Yomitan Pottery village. The 13-chamber climbing kiln is the largest in Okinawa and is fired five times a year. After loading the large kiln with thousands of pieces of pottery, Kitagama masters and their students work in shifts around the clock for three full days and nights to feed the flames. The temperature inside the kiln reaches as high as 1400 °C (2552 °F).

“It takes a lot of effort to keep these precious techniques now,” Sajiki said. “Many potters have moved away from traditional firing techniques and styles. Kitagama maintains the traditions very faithfully.”

Kitagama’s four masters -- Yoneshi Matsuda and his twin brother Kyoushi Matsuda, Masataka Miyagi and Masanori Yonaha -- welcomed the scientific collaboration with OIST. While they are world-class potters, they did not know exactly why their methods worked.

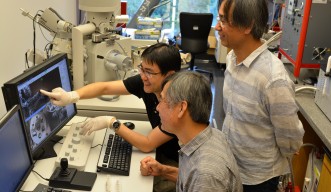

Sajiki and OIST researcher Anya Dani used advanced instrumentation, including X-ray Diffraction, X-ray Florescence Spectrometer and a scanning electron microscope, to analyze the precise composition of clay mixes and glazes. They also put thermometric chips throughout the kiln during the firing, so potters now have a more precise understanding of the temperature gradient throughout the chamber. Combining these measurements, the researchers were able to precisely document the ideal combination of heat, oxygen, glaze chemistry and clay mixture that produces the perfect pottery.

Having this information recorded ensures these traditional techniques will be preserved for future generations, unlike some historic methods that have been forgotten over time.

For press enquiries:

Press Inquiry Form