Ice for AC: Time-Shifting Electricity Consumption to Save Money and Level Demand

One of the advantages of being at OIST is the location – sunny Okinawa, a subtropical island surrounded by coral reefs and translucent blue water. However, “sunny” and “subtropical” usually mean “hot” and “humid,” and scientific experiments, offices, and high-performance computing facilities require an environment where temperature and humidity can be carefully controlled.

Ice is one key to saving money on cooling costs. Tucked away beneath the administrative offices and meeting rooms of the Center Building is a tank of over 540,000 liters of water. Every night, two huge “super-coolers” freeze this water, producing a block of ice weighing over 180 tons – more than a fully-grown blue whale. During the day, three large pumps circulate water through pipes built into this tank. The chilled water is then circulated through radiator pipes in the Central and Lab 1 buildings where it absorbs heat from the air.

The pumps start every morning at 8 AM, and usually by 5 PM the ice has all melted, leaving the remaining heat of the evening for conventional air conditioners to handle. The resulting decrease in daytime electricity consumption amounts to approximately 1,000 kilowatts per hour.

Such “heat accumulation systems” save money because the ice is created at night, when electricity is cheapest, but the benefits extend beyond simple penny-pinching. Because electricity cannot be efficiently stored, power companies have a surplus of energy during low-demand times, like the middle of the night, and a shortage of electric production capacity during the day, when air conditioning systems all over the island have to work extra hard. This is the reason that nighttime energy rates are lower.

For power companies, adding generators to produce more electricity during peak periods means installing and maintaining costly machines which sit idle during low-demand periods. By using nighttime electricity to reduce daytime demand, OIST saves money and at the same time helps the power company to operate more efficiently.

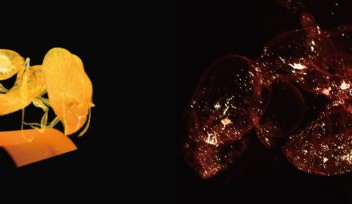

In the left foreground and right background, the two super-coolers which freeze the water in the tanks every night.

Building maintenance workers monitor the Safety Control Center, where everything from lighting to door locks, air conditioning, and security are centrally controlled.

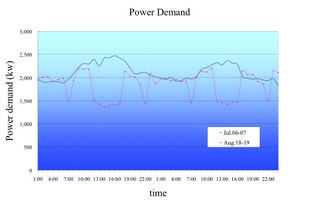

This graph compares power demand with and without the heat accumulation system running. The blue line is the demand from 6-7 July 2010, when only conventional air conditioning was being used; the pink line shows the power demand from 18-19 August 2010, when the heat accumulation system was up and running. These two-day periods had comparable outdoor temperatures, and yet the difference in average peak daytime power demand between them amounts to approximately 1,000kw per hour.

For press enquiries:

Press Inquiry Form