The Glass Revolution

3D printing today is linked with innovation. Every day more products are created through 3D printing, from tiny teeth to massive jet engines. Now, at the Okinawa Institute of Science and Technology Graduate University (OIST), scientists will create delicate and intricate tools for research starting from transparent glass and utilizing a newly installed 3D printer that uses selective laser-induced etching (SLE) technology.

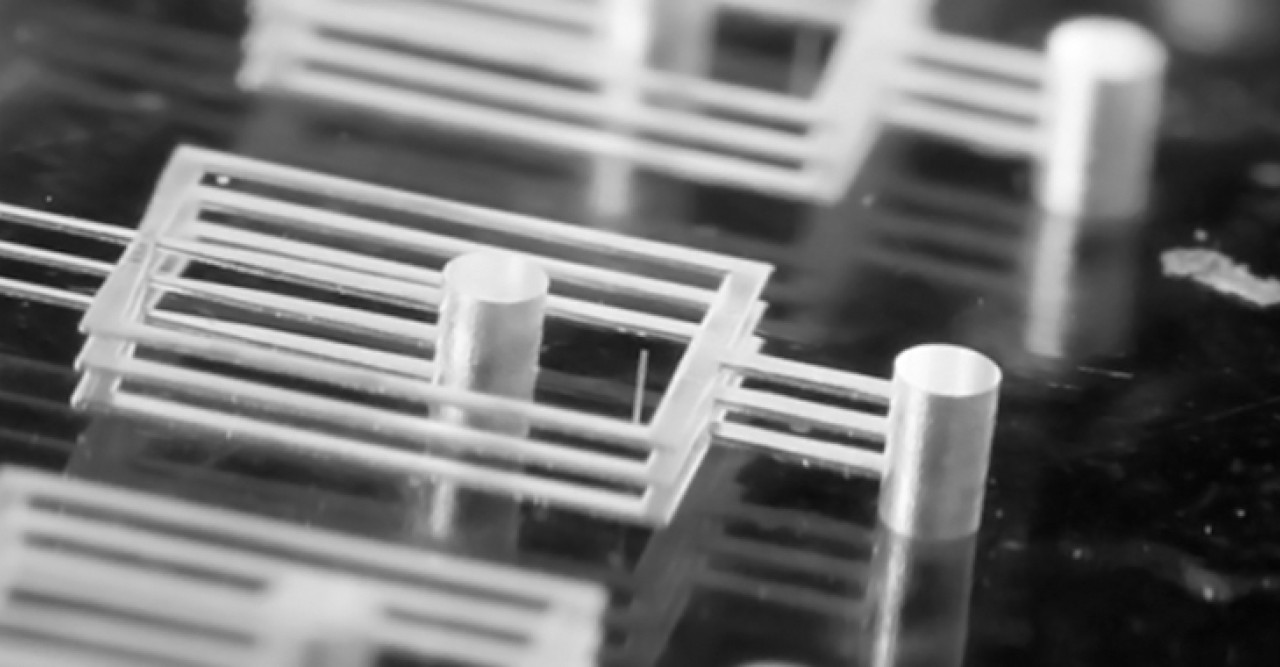

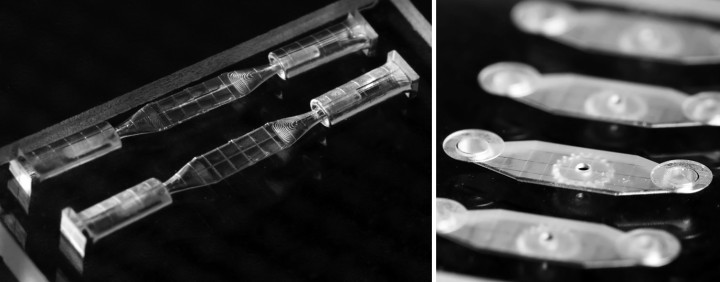

SLE technology is a two-step process that produces 3D structures in transparent materials. First, a machine writes inside the material from bottom to top, layer by layer, modifying the glass with a laser. Thanks to this modification, which happens at a molecular level, it is then possible to chemically remove the altered glass from inside the microscopic channels previously written, as the material is placed in a chemical bath. This process is the opposite of ordinary 3D printing: the material is not added, but subtracted. The technology enables the manufacture of very complex and extremely small glass tools.

The process is extremely fast, as the machinery is also capable of drilling 50 holes per second in 1mm glass, and the applications are numerous and diverse. For example, researchers will be able to create complex 3D cavities, which are the basis for micro fluidic structures, together with filtering applications, nozzles, mixer and reaction chambers. Furthermore, scientists will make micro mechanics in fused glass, such as already assembled free rotatable gears.

Dr Kieran Deasy, Physics Research Support Specialist in the OIST Mechanical Engineering & Microfabrication Support Section, will take care of the newly installed 3D printer. He is enthusiastic about the future applications that will be explored at OIST. “I am excited to see how OIST researchers will use this machine. I am confident that here new applications can be discovered thanks to the multidisciplinary approach that characterizes this institution.”

For press enquiries:

Press Inquiry Form