One Reaction, Two Results, Zero Waste

Finding new and effective ways to create alcohols and esters is a constant target in chemistry, as these substances are important industrial compounds and feedstocks – the raw materials from which many industrial processes start. Alcohols have numerous medical and industrial applications, such as drugs and antifreeze. Esters, a class of organic compounds, are utilized by the food and cosmetics industries to add specific flavours to food or perfumes. The processes to create alcohols and esters have typically been carried out under harsh conditions, with high temperatures and caustic reagents that leave behind pollutant waste.

Two researchers at the Okinawa Institute of Science and Technology Graduate University (OIST), Dr Abhishek Dubey and Dr Eugene Khaskin, have now found a single chemical procedure that can create alcohol and esters without generating any waste and avoiding the use of harmful reagents. The researchers work in the OIST Coordination Chemistry and Catalysis Unit and in the Science and Technology Group, and their findings are published in ACS Catalysis.

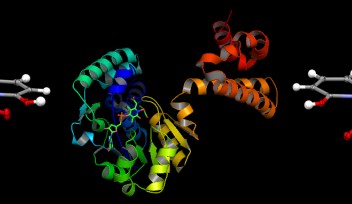

Dubey and Khaskin started with a known concept in organic chemistry called metathesis, where molecules are scrambled, and wondered whether it could be applied to esters. Eventually, they hit on the right formula: their reaction breaks and reforms the connections between the core of an ester and its peripheral fragments, re-arranging the fragments in four different ways. “According to this rearrangement, we should get four possible products, and that’s what we see,” Khaskin said. “We start with one ester, and we end up with four: one that is the same as the ester we started with, and the three others that are chemically possible.”

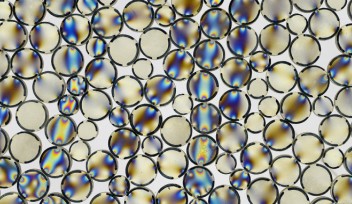

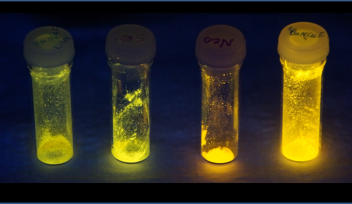

Depending on their structure, esters have very different smells. As each one of the new products has a specific molecular arrangement, their smell is completely different. The smells also change quite dramatically depending on how far the reaction has progressed. “The scent of the resulting mixture depends on its components, and you often get a pleasant, fruity surprise when you stop the reaction and open up the vial,” Khaskin commented. “Usually in chemistry, unlike back home in the kitchen, it’s not a good idea to smell what you’re cooking, but this is one of the perks of working with esters.”

The process is also uncomplicated. “Our process has one step: you find an ester that can rearrange into the esters you need, you just put that starting ester in the flask, add a catalyst, heat everything at the appropriate temperature, and after few hours, it’s done,” Dubey explained. “It is a more straightforward, simpler process.” While the esters created during this process are known, the method has the potential of creating new molecules and new mixtures.

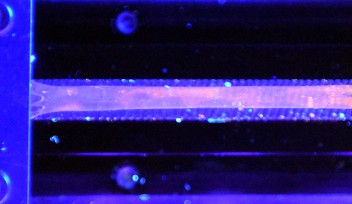

And it gets better. Slightly tweaking the reaction conditions – adding ethanol to the same reaction – transforms the starting ester into an alcohol. Creating alcohols from esters is usually a difficult process that involves high-pressure hydrogen and specialized equipment. But the new process does not require any of this: it is safer and easy to perform.

“Both reactions have not been reported before,” the scientists commented. “They represent an economical, green-chemistry alternative to previous synthetic routes.”

Specialty

Research Unit

For press enquiries:

Press Inquiry Form